3.3.2.1 Principles of Prevention for Electrical Flashover

Where the arc flash hazard cannot be eliminated then suitable risk controls should be in place with preventative measures taking the priority. Article 6(2) of European Council Directive 89/391/EEC EU (Workplace Health and Safety Directive) states “Where an employer implements any preventative measures, he shall do so on the basis of the principles” shown below. This is also specified in Management of Health and Safety at Work Regulations 1999 schedule 1. My interpretation of each of the nine principles of prevention when applied to the arc flash hazard is shown in italics.

- Avoiding the Risk - which means Dead working, Not energised = No electrical danger

- Evaluation of the risks which cannot be avoided - by arc flash assessment and predicting the level of harm and likelihood

- Combating the Risks at Source - by designing out the arc flash hazard or reducing it to an acceptable level, even as a temporary measure for the period of work

- Adapting to the individual - limiting exposure to the hazard

- Adapting to Technical Progress/Information - take advantage of technological and technical progress to improve both safety and working methods. The evaluation of the hazard has progressed, as have mitigation and protection techniques in respect of arc flash

- Replacing the dangerous with the non-dangerous - replace vulnerable legacy switchgear and control panels preferably with arc protected equipment and/or high levels of insulation and segregation of control and power circuits. Using safer equipment (e.g. test equipment) and tools (e.g. insulated)

- Developing a coherent overall prevention policy - create a safe procedures approach which is specific to structure environment, workforce and equipment issues and developing risk-based investment to reduce exposure to the hazard

- Giving collective protective measures priority over individual protective measures - create a safe place of work approach by screening live parts and by good design. Any measure that is not dependent upon the individual’s choice

- Giving appropriate instruction to employees - create a safe people approach by documenting safe systems of work and training employees in safe work practices. Highlight the arc flash hazard and provide information such as in the labelling of switchgear

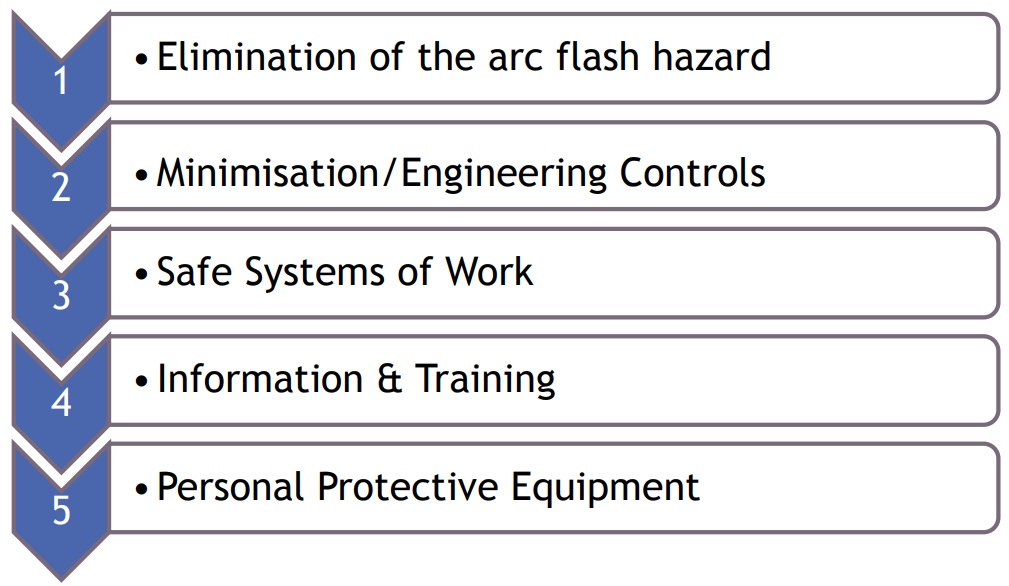

These general principles of prevention should be considered against a hierarchy of risk controls with priority as given below. The top of the list should always take priority with PPE as a last resort.

3.3.2.2 Hierarchy of Risk Controls for Electrical Flashover

All these measures should be properly monitored and reviewed, and this is particularly important when considering the lower order risk controls such as personal protective equipment.

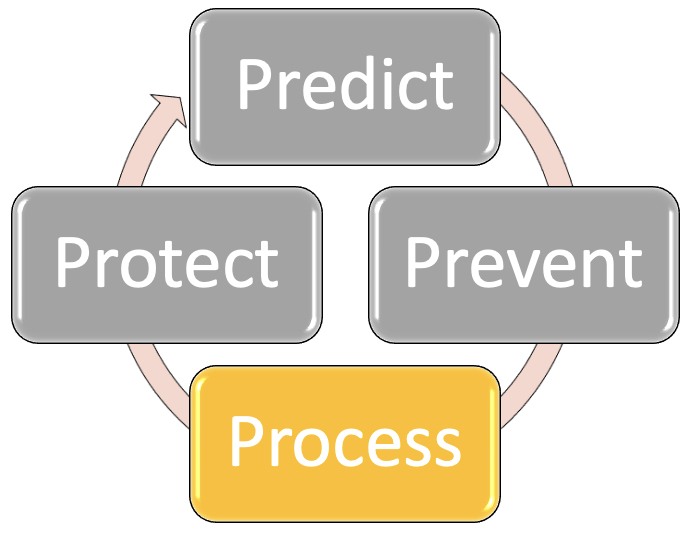

3.3.3 Process

The next step is to review policies and procedures. A review of electrical procedures and safe systems of work can substantially raise the profile and understanding of the arc flash hazard and associated control measures. Periodic awareness and refresher training, toolbox talks and specific training in the policy, rules and procedures are essential elements of arc flash risk management.

Chapter 6: Process, Policies and Procedures, and Chapter 9: Electrical Duty Holders introduce the concept of the three building blocks of electrical safety which are safe procedures, safe people and safe places. I highlighted these three facets of electrical safety in the list of principles of prevention above. (3.2.1 points seven, eight and nine)

The Process, Policies and Procedures chapter gives practical guidance on how these three facets address the specific issues of arc flash management. In particular, there is detailed information on a practical approach to risk assessment. Risk Assessments need to document the hazard severity and the risk control measures. Wherever possible these should be dynamically produced, and task based. In other words, be available to the person carrying out the work who will reassess such things as environmental conditions and equipment state. The chapter also provides guidance on competence (safe people) and maintenance (safe places). The Electrical Duty Holder chapter breaks down and explains the concept of safe procedures, safe people and safe places in much greater detail when applied to arc flash risk management.

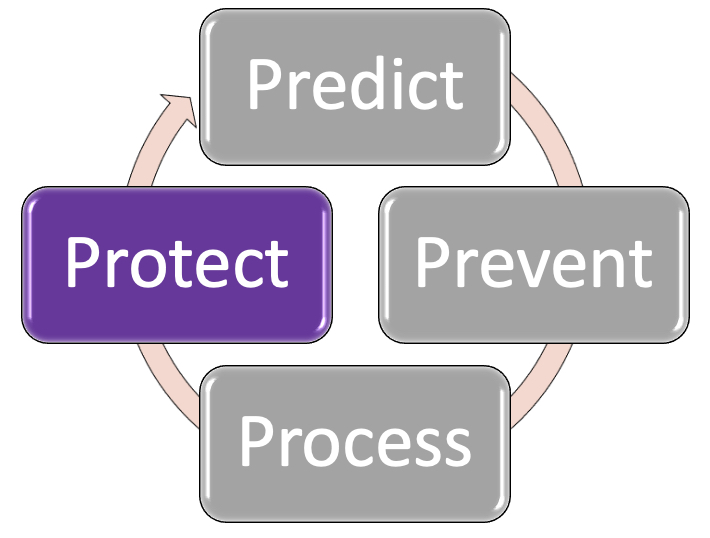

3.3.4 Protect

Where the risk cannot be controlled by prevention or where there is a residual risk of injury then it may be necessary to consider mitigation to prevent injury to the worker. The requirement for and suitability of mitigation techniques must form an essential element of any risk assessment. Where protection against the thermal effects becomes necessary it must be emphasised that PPE does not prevent the accident happening in the first place.

Non-flame-resistant clothing may ignite or melt at lower incident energy values and once ignited will continue to burn after the electrical arc has been extinguished. Burning material next to the flesh can result in serious third degree burns even for very short durations. This means that ordinary clothing could actually become a hazard and for this reason it should be considered within the risk assessment. Part of the risk assessment is to define the level of PPE that should be worn by the worker. However, the removal of the hazard is always the first choice.

- Risk assessments are a mandatory part of safety management which require an evaluation of risk in every case. That includes arc flash in the same way as any other hazard.

- Prevention is the first key principle. If the equipment is dead and correctly isolated, then there is no hazard.

- Never use PPE as a first line of defence against electrical flashover. It should be used as a last line of defence and any protection against residual risk using PPE is likely to be more comfortable, cheaper, and easier to justify if the 4 Ps approach is used.