STEP 6. AUTHORISE.

Even though we are speaking here about low voltage isolations, an electrical permit to work system is beneficial for any complex commercial or industrial site. The following is meant as a brief overview only, but a permit system should be carefully considered and be drafted into electrical safety rules. A permit to work should always be issued where the designated person undertaking the isolation is not the one who is going to do the work and self-permitting is to be discouraged. The specific circumstances where a low voltage permit to work can be issued are:

- Where the designated person is isolating for others.

- For multiple working parties.

- For complex isolations where there may be more than one point of supply.

- Where third parties such as a utility company are involved in isolating their equipment to provide you with a point of isolation.

- Switchgear with automatic changeover or remote-control switchgear and equipment controlled by phase failure relays.

- Extensions to switchboards or control panels.

- Isolations from Generators and UPS equipment.

- Stored energy systems (either mechanical or electrical).

- Isolations lasting more than one shift.

The list is not exhaustive and there may be other situations requiring the use of permits.

6.12 Live Testing, Fault Finding and Diagnostics

Testing for fault finding, diagnostic or commissioning purposes on live equipment, is live work and precautions should be taken to reduce the risk of arc flash (and electric shock of course) to as low as is reasonably practicable. If workers are routinely testing on very high incident energy circuits, I would suggest that Chapter 5: Prevention & Minimisation should be revisited as a matter of urgency. The use of extra low voltage and/or segregation of control circuits from power circuits is always the desired option and if that is not possible because of legacy equipment design then the following checklist may help to prevent accidents.

6.12.1 Live Testing Risk Assessment Checklist for Low Voltage Equipment

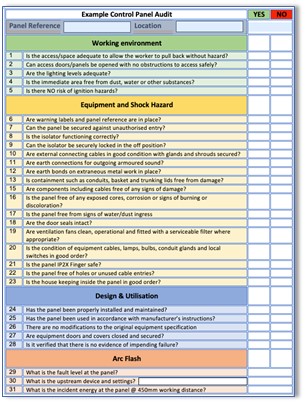

Figure 6.11 Example of a Control Panel Audit Form

Planning for Safety. If the live testing is for diagnostics or fault finding, I would suggest that an equipment audit will be a good start. There is an example of a control panel audit form which can be used as one part of the audit step in Chapter 9: Electrical Duty Holders. It will be an opportunity to not only deal with the arc flash risk but also very effectively take stock of equipment which is likely to have the greatest number of interactions and therefore risk in terms of likelihood of electrical incidents.

Incident Energy Level. As described earlier, knowledge of what the incident energy level is will allow for a decision on how to proceed. Decisions should be based upon risk assessment especially in respect of whether to deploy PPE or not. As I stated under testing for dead, I would suggest a minimum of hand protection regardless of the incident energy levels for low voltage testing comprising of insulating gloves and leather over gloves. Consider also the routine wearing of face and eye protection for live testing.

Competence. A high degree of competence is required for live testing and although I have said it previously under dead testing, it is worth repeating. Competence means that the worker must have the skill, knowledge, attitude, training, possess the experience to undertake the work and has the ability to recognise the extent of their own competence and leading them to take appropriate action. Specific requirements over and above general electrotechnical knowledge are that he/she will have an adequate understanding of the system to be worked on and practical experience of that class of system, an understanding of the hazards which may arise and the precautions which need to be taken and an ability to recognise at all times whether it is safe for work to continue. What I would add here is that multi-skilled “technicians” are often used for fault finding on electrical equipment whose first calling may not be electrical. I can relate many experiences of this approach which are quite uncomfortable, and this is a route that needs skill and care that such individuals have the necessary electrotechnical knowledge to avoid endangering themselves or others.

Secure the work area. Sufficient space should be provided and maintained around the equipment to permit safe testing. Make sure that tripping and slipping hazards are removed and the work area is under the complete control of the person undertaking the tests. This could be by accompaniment and/or the area is demarcated or defined with barriers.

Work at height. Both the arc flash and electrical shock hazards could be made much more deadly when testing or carrying out any other work on or near live equipment at high level. Special consideration should be given to working at height in the risk assessment with a view to avoidance. Even minor arc flash incidents at height can cause falls or in one case that I know about, injury by jumping from a mobile elevated work platform.

Keep the work to a minimum. The work should be kept to a minimum and the panel doors and access should be secured at breaks or at the end of a shift.