7.4.2 User acceptability

Comfort

If the garment is to be worn as part of everyday workwear, then it needs to be comfortable. In addition to the thermal performance per weight of fabric, it has to feel comfortable as well as be lightweight. This is often termed as the hand of a fabric and is assessed by the reaction obtained from your sense of touch. The challenge with measuring fabric hand is that everyone perceives things differently. The air-permeability of the fabric and a good garment design are parameters, which determine the comfort of protective clothing. Comfort is not only another key aspect for acceptance of the clothing by workers, but if the garments are very uncomfortable then this may even increase the risk of an electrical accident or even trip, slips and falls.

Colour

In addition to being comfortable, if the garment is to be worn as part of everyday workwear, then it needs to look good, and colour could be important to gain user acceptability. The problem is that inherently flame-resistant fibres may be limited in colour ranges so this is where compromises may be required. Durable appearance and colour fastness are also a key element for acceptance of clothing by workers and evidence should be available from the supplier.

Life Expectancy

There needs to be a discussion about the life expectancy of any garment and which factors will affect it. From the data that I have seen, it is likely that inherently flame resistant fabrics will last longer than permanently treated fabrics, but purveyors of the latter type may be able to give a contrary viewpoint. The life cycle cost could vary widely and an inability to provide evidence could result in a much greater expense for an inferior product.

Laundering

The standard allows for both washing and dry cleaning, but it is down to the manufacture to make clear how the garments have to be cleaned in their instructions. This could have a significant effect on life cycle cost. The manufacturer may state a maximum number of cleaning cycles, in which case the requirements for limited flame spread have to be met after the stated cleaning cycles. Otherwise, if no maximum number of cleaning cycles is specified, the flame test has to be carried out after five cleaning cycles.

Underwear

Arc rated under garments are available and their provision does ensure that workers are equipped with non-flammable clothing throughout. Another advantage is that higher levels of protection can be obtained when used as part of a layered solution as described above. In Europe however, the provision of undergarments as part of a PPE system has some drawbacks. The employer must provide it free of charge and they also have an audit inspection role to ensure that it is being worn. The complications such an audit will bring, I will just leave to your imagination. From a practical perspective, it may be better to mandate that the worker must not wear undergarments or clothing made of materials that would add to the hazard of possible burns. This is where the specifier may find that the open arc Incident Energy Limit (ELIM) rating has a part to play, insomuch that there is a zero chance of burn injury. It follows that undergarments cannot ignite for properly rated FR PPE in an arc flash incident. See section 7.5.2 for further information about ELIM.

Labels

Figure 7.3 IEC Garment Symbol

Every arc resistant garment has to be labelled which should show the manufacturer, type of product, size, and care requirements. In addition, the garment will have the IEC arc flash symbol shown in Figure 7.4 which denotes protection against the thermal effect of the electric arc. It should also show the level of arc thermal protection in the form of an arc rating ELIM and/or arc protection class (APC 1 or APC 2). In addition to ELIM the lower value of either ATPV or EBT (Energy Breakopen Threshold) can also be added. All basic essential guidance with respect to cleaning should be given by labels or other marking of an item of PPE. More detailed additional information will be given on instruction for use/manufacturer’s leaflets.

Layering

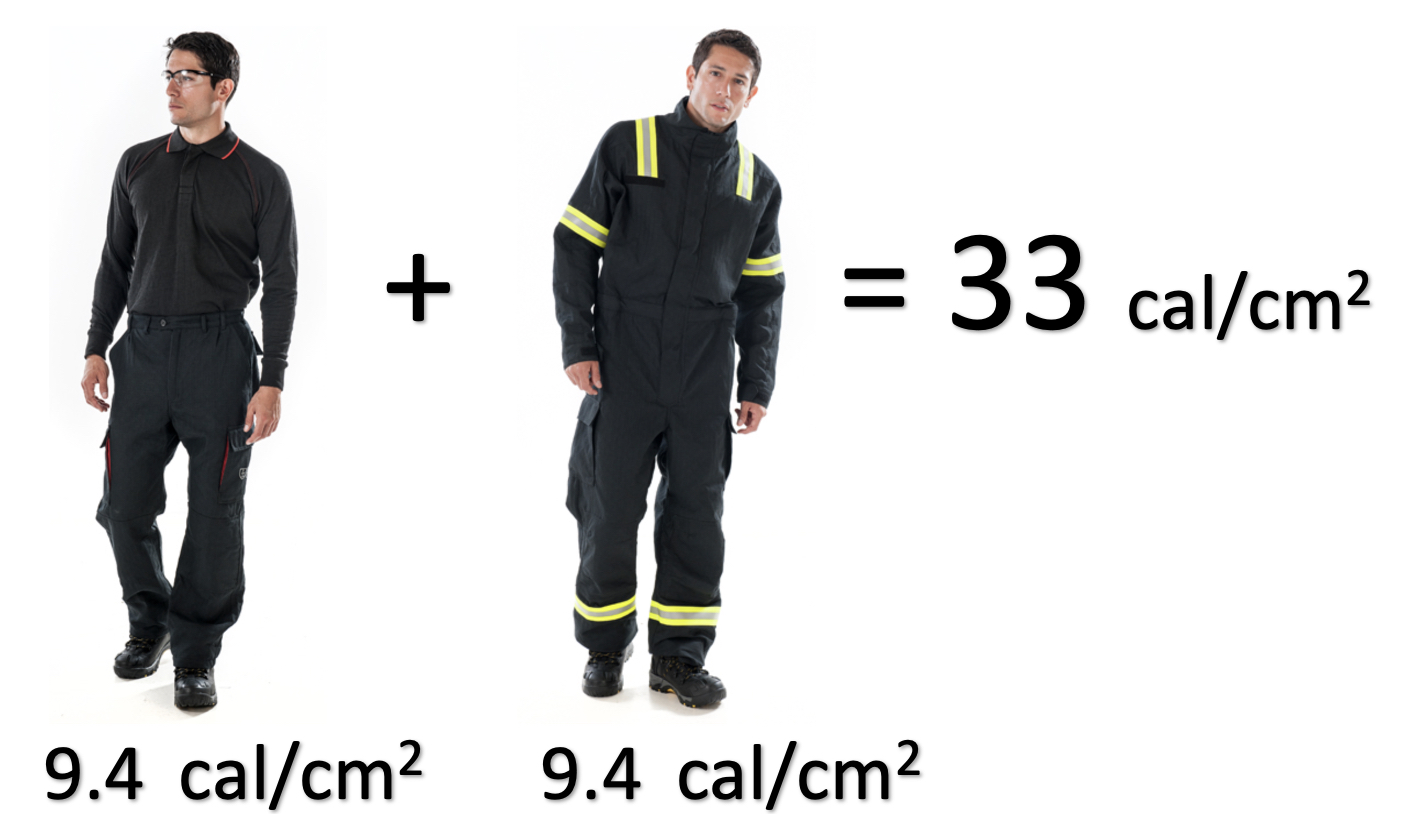

The layering of arc rated garments can have a beneficial effect on the final arc rating as well as comfort. For instance, if an arc rated jacket of 8 cal/cm2 is worn over an arc rated shirt of 8 cal/cm2 it would suggest that the final Arc Thermal Protection Value (ATPV) will be of the order of 16 cal/cm2. The fact is that the final ATPV if the garments were to be used together would be considerably higher than that. This is often used by suppliers to produce higher comfort levels from higher rated garment systems. It should be stressed that layering has to be tested as a system together to assure their protection level. The following diagram (Figure 7.4) shows how two layers of 9.4 cal/cm2 results in a final tested ATPV of 33 cal/cm2. See section 7.5.2 for further information about ATPV.

Figure 7.4 Layering of Protection Example