Electrical Duty Holders

The scope of this chapter is help duty holders to discharge their responsibilities specifically around the management of the arc flash hazard. Electrical duty holders are classed as anybody who works with electricity and their duties relate to all those matters that are within their control. For the purposes of this chapter, the electrical duty holder is the one who has prime responsibility and the resources to provide a safety management system for any facility. So, if you identify yourself as that person, the following are specific measures that you can take to help with your decision making in respect of the arcing hazard.

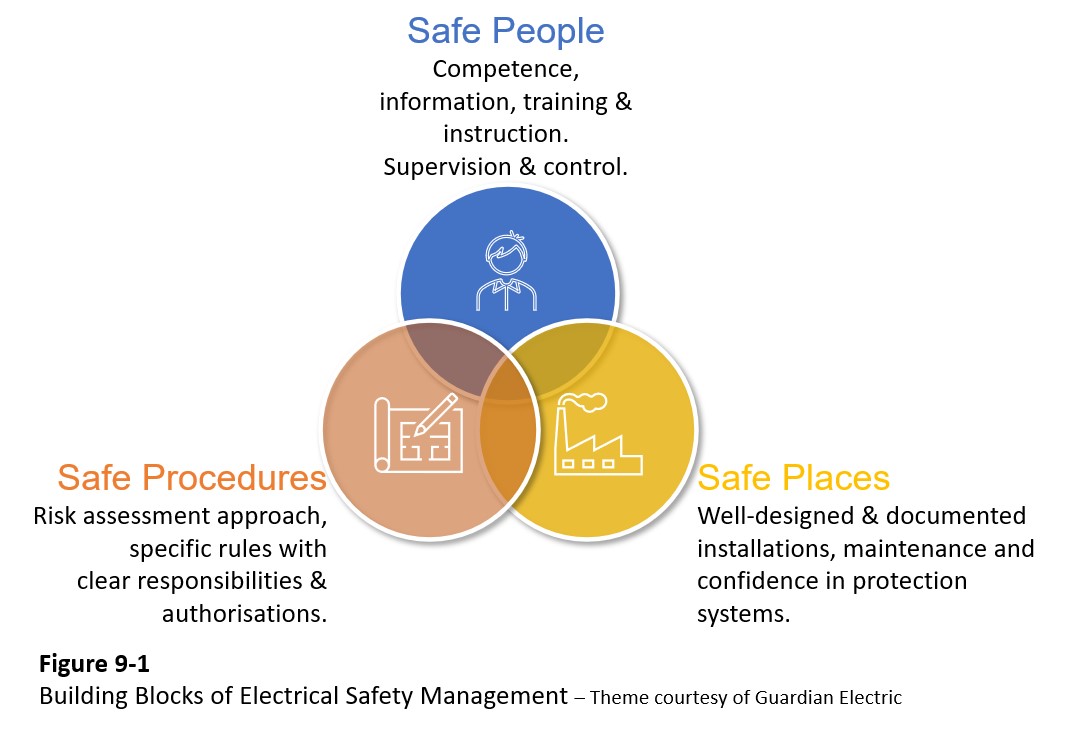

In EN 50110-1:2013 Operation of Electrical Installations, the duty holder will be termed as the “person responsible for an electrical installation”. This person is defined as the nominated person with the overall responsibility to ensure the safe operation of the electrical installation by setting rules and organisation or framework. In Chapter 6: Process, Policies and Procedures, the need is identified for establishing the responsibilities of stakeholders for implementation, planning, control, authorisations, audit and review. This should identify duty holders in respect of an electrical safety management system encompassing safe procedures, safe people and safe places as shown in Figure 9.1.

Figure 9.1

9.1 Safe Procedures, People and Places

It is against the above model that we can frame some of the key actions that we need to take as duty holders to manage the arc flash risk. Whilst not exhaustive, (depending upon the organisation and environment), these key actions are detailed in the following arc flash specific checklists. Note that the safe procedures, people and places model overlaps indicating that these facets are mutually dependant. To give an example, a safe place of work depends not just on the original safe design of the electrical system, it is also dependent upon having competent persons maintain its condition following suitable procedures to keep it that way.

9.1.1 Safe Procedures Checklist

- Risk Assessment. This takes into account the 4P approach. In other words, to predict the level of harm from a possible arc flash and then to prevent from it causing harm. More specifically, we will identify the hazard and those at potential risk of harm, estimate or predict the severity, eliminate or prevent the risk and finally by mitigation protecting those at risk of harm.

- Approval of Electrical Test Equipment, PPE and Tools. Formal control and approvals process for all electrical test equipment, insulated tools, locks, labels, insulating tools, matting, shrouding and electrical PPE.

- Clear responsibilities and authorisations. Individuals for any high-risk activities should be identified with a clear list of responsibilities and then authorised in writing.

- Establish dead working as a principal requirement. Work on or near live exposed conductors should rarely be permitted. Plan and programme the work to allow work to be carried out where possible with the equipment dead.

- Specific controlled circumstances for live proximity work. Be clear about which activities could be sanctioned and under which circumstances. Employ further control measures to meet the risk.

- Clear instructions on where live working is strictly forbidden. Be very clear about which live working tasks are forbidden.

- Monitoring and Review. Where reliance is put on procedures and protection in the management of the risk, there is a high need to ensure that those controls are working properly and reviewed accordingly.