Process, Policiies & Procedures

Very often electrical workers, management and duty holders do not fully understand the nature of the arc flash hazard and the seriousness of the injuries that can be sustained. As a result, experienced personnel are frequently involved in these types of accidents. Competent electrical workers should be trained in the decision-making process necessary to determine the degree and extent of the hazard and job planning necessary to perform the task safely.

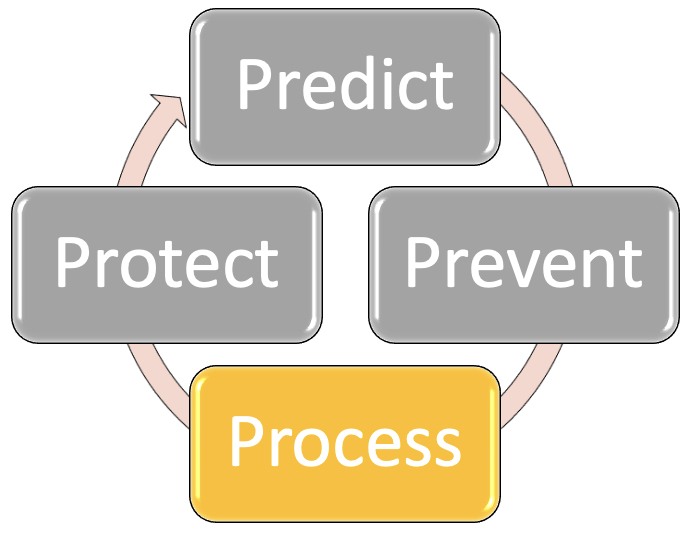

A review of electrical procedures and safe systems of work can substantially raise the profile and understanding of the arc flash hazard and associated control measures. Periodic awareness and refresher training, toolbox talks and specific training in the policy, rules and procedures are essential parts of arc flash risk management.

“Most electrical accidents occur because individuals are working on or near equipment:

- which is thought to be dead, but which is in fact live;

- which is known to be live but those involved are without adequate training or appropriate equipment, or they have not taken adequate precautions.”

This is a quotation that I have used many times and is taken from the UK HSE guidance booklet Electricity at Work – Safe Working Practices, HSG 85. This defines the key issues that need to be addressed and sets out a starting point for anyone reviewing electrical policies and procedures or maybe writing them for the first time.

6.1 Safe Procedures, Safe People and Safe Places.

Chapter 9: Electrical Duty Holders expands on the concept of the three facets of electrical safety which are safe procedures, safe people, and safe places. Whilst this chapter deals with safe policies and procedures, it also overlaps with safe people in dealing with competence and guidance on maintenance procedures which impact on safe places.

Figure 6.1 Building Blocks of Electrical Safety Management - Theme courtesy of Guardian Electric

Chapter 9: Electrical Duty Holders, breaks down and explains the concept of safe procedures, safe people and safe places in greater detail when applied to arc flash risk management.

6.2 Safety Rules and Procedures

High voltage safety rules and procedures are often straightforward to create and implement because the interactions with equipment and the competence of staff is easier to define. Low voltage rules and procedures can be more difficult because the nature of the work often entails the use of many more staff with different levels of competence. The interactions on or near live equipment is likely to be much higher and those undertaking the work may be contractors as well as staff. It is because of this complexity at low voltage, that rules and procedures need to be very specific to the organisation and environment. As a minimum, a key ingredient should include a robust set of safety rules with the following elements:

- How the rules address company health and safety policy.

- Clear responsibilities of stakeholders for implementation, planning, control, authorisations, audit and review. This should identify duty holders in respect of an electrical safety management system encompassing safe people, safe places and safe procedures. See Chapter 9: Electrical Duty Holders

- Specific authorisations of the individual for electrical activities which implies a rigorous assessment of competence.

- Establish dead working as a principal requirement.

- Specify controlled circumstances for live proximity work such as diagnostic testing, running adjustments and inspections.

- Have clear instructions on where live working is strictly forbidden such as the removal and replacement of live components.

- Auditing, monitoring and review